HOME >> technology

Non-woven Fabric

Non-woven fabric or nonwoven cloth, is composed of directional or random fibers. It is a new generation of environmentally friendly materials. It is moisture-proof, breathable, flexible, light, non-combustible, and easy to decompose. It is also non-toxic, non-irritating, rich in color, with low price, recyclable and so on. Non-woven fabric (PP material), which is made from polypropylene granules as raw material, for example, is produced by continuous one-step method of high-temperature melting, spinning, laying, hot-pressing and rolling. It is called cloth because of its appearance and certain properties similar as cloth.

Non-woven fabric has no warp and weft threads, it is very convenient to cut and sew, and it is light and easy to shape, so it is popular with craft lovers. That is because it is a kind of fabric that does not need to be spun or woven, which is produced just by oriented or randomly arranging the textile short fibers or filaments to form a web structure, and then reinforcing those by chemical methods such as mechanical, thermal bonding and so on. It is not made of interwoven and knitted yarns one by one, but the fibers which are directly bonded together by physical methods. Therefore, when you get the sticky lining of your clothes, you will find that it is impossible to draw a single thread. Non-woven fabric breaks through the traditional textile principle, and has the characteristics of short process flow, fast production rate, high output, low cost, wide use, multiple sources of raw materials and so on.

A. About Polypropylene

1. Polypropylene (PP for short) is a kind of semi-crystalline thermoplastic, and it is a by-product of petroleum refining. It has high impact resistance, strong mechanical properties, resistance to a variety of organic solvents and acid and alkali corrosion. It is widely used in industry and is one of the common polymer materials.

2. Chinese name: 聚丙烯

3. English name: Polypropylene

4. Chinese alias: 丙纶油剂;丙纶;丙纶FDY;丙纶长丝FDY;丙纶短纤;丙纶短纤维;聚丙烯短纤维;PP

5. English alias: Propylene Resin (Low M.Wt:)

6. CAS Number: 9003-07-0

7. Molecular formula: (C3H6)n

8. Molecular weight: 42.0804

B. Non-woven Fabric Characteristics

1. Non-woven fabric is a kind of fabric that is not woven, it is directly produced by forming a web structure with polymer chips, short fibers or filaments through airflow or mechanical method, and then reinforcing it by hydroentangling, needle punching, or hot rolling, and finally readjusting it for finished product. It is a new type of fiber product that is soft, breathable and with flat structure. The advantage of non-woven fabric is that it does not produce fiber crumbs, and it is strong, durable, and silky soft. It is also a kind of reinforcing material, and it has a cotton feel. Compared with cotton, non-woven bags are easy to shape and cheap to manufacture.

2. Water-repellent and breathable: Polypropylene slices do not absorb water, have zero moisture content, and the finished products have good water-repellent properties. It is composed of 100% fibers and has porousness as well as good air permeability. It is easy to keep the cloth dry and it is easy to wash.

3. Non-toxic, non-irritating: The product is produced with FDA food-grade raw materials, does not contain other chemical components. It has stable performance, it is non-toxic, non-odor, and does not irritate the skin.

4. Antibacterial and anti-chemical agents: Polypropylene is a chemically blunt substance, not moth-eaten, and can isolate the erosion of bacteria and insects in the liquid; antibacterial, repellent to alkali corrosion, and the strength of the finished product will not be affected by erosion.

5. Antibacterial: The product is water-repellent, not moldy, and can isolate the erosion of bacteria and insects in the liquid, and is not moth-eaten.

6. Good physical properties: It is produced directly by spreading polypropylene spun filament into net and thermally bonding it. The strength of the product is better than that of ordinary staple fiber products. The strength is non-directional and it is similar in the vertical and horizontal directions.

7. In terms of environmental protection, the raw material of most non-woven fabrics currently used is polypropylene, while the raw material of plastic bags is polyethylene. Although the names of the two substances are similar, their chemical structures are quite different. The chemical molecular structure of polyethylene is very stable and extremely difficult to decompose, so it takes 300 years for plastic bags to decompose; while the chemical structure of polypropylene is not strong, the molecular chain of which can easily break, so that it can effectively decompose, and enter into the next environmental cycle in a non-toxic form. A non-woven shopping bag can completely decompose within 90 days. Moreover, non-woven shopping bags can be reused more than 10 times, and the pollution to the environment after disposal is only 10% of that of plastic bags.

Attached: Disadvantages

1) Compared with textile fabrics, it has less strength and durability

2) Cannot be washed like other fabrics

3) The fibers are arranged in a certain direction, so it is easy to split from the right angle direction and so on. Therefore, recent improvements in production methods are mainly focused on improvements to prevent splitting.

C. Classification of Non-woven Fabrics

According to different material components, non-woven fabrics can be classified as:

1. Polypropylene Non-woven Fabric (PP Non-woven Fabric)

Polypropylene fiber is a synthetic fiber made from propylene, a by-product of petroleum refining. Polypropylene spunbond non-woven fabric is a kind of cloth which is with polypropylene as raw material, polymerized into a net through high temperature drawing, and then bonded into a fabric by hot rolling. Because of its simple process, large output, and non-toxic and harmlessness to the human body, it is used widely. The vast majority of non-woven handbags on the market are using polypropylene non-woven fabric as material. Polypropylene non-woven fabric has many advantages, such as good air permeability, filtration, heat preservation, water resistance, etc., and the non-woven fabric is an environmentally friendly product.

2. Polyester Non-woven Fabric (PET Non-woven Fabric)

The polyester non-woven fabric is made of polyester chips as the raw material and hot rolled by spunbonded filaments. The performance of polyester non-woven fabric is better than that of polypropylene non-woven fabric, mainly in: strength, wear resistance and other properties. Heat resistance of polyester non-woven fabric is better than that of polypropylene non-woven fabrics. Polypropylene non-woven fabric has obvious heat shrinkability, and normally it will shrink significantly when the temperature reaches 140 degree. Polyester will not shrink until the temperature reaches 230 degree, so polyester non-woven fabric can be used for high-temperature sublimation, but polypropylene cannot. Anti-aging of polyester non-woven fabric is better than that of polypropylene non-woven fabric. Although the performance of polyester non-woven fabric is completely superior to that of polypropylene, the cost of polyester non-woven fabric is high, and polypropylene is still selected for non-woven bags on the market.

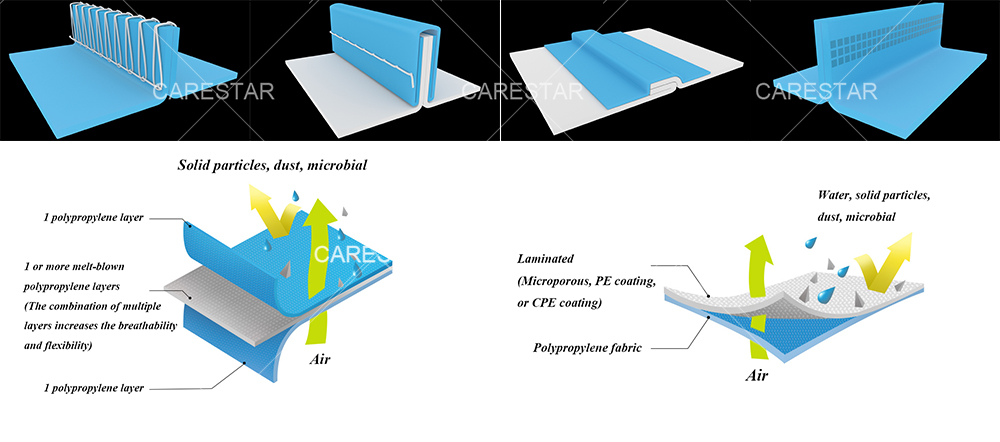

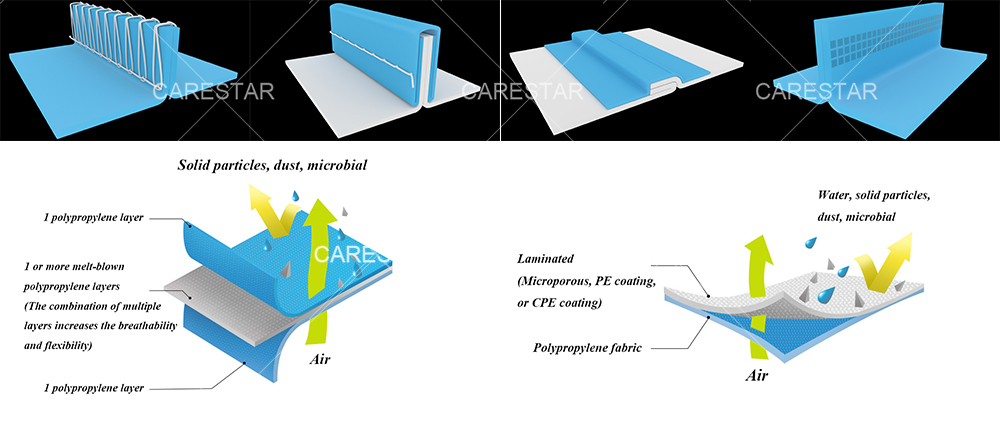

3. SMS Non-woven Fabric

This kind of non-woven fabric is a composite non-woven fabric, which is a composite product of spunbond and meltblown. At present, it is mainly used in medical and health labor protection products, such as surgical gowns, surgical caps, coveralls, etc.. SMS non-woven fabric is non-toxic, tasteless, and highly effective in separating bacteria. Through special treatment, it can also achieve properties of anti-static, anti-alcohol, anti-plasma, water-repellent and so on.

4. Non-woven fabrics are classified as the above three kinds according to the material. In addition, there are nylon (PA), viscose fiber, acrylic fiber, polyethylene fiber (HDPE), and chlorinated fiber (PVC).

Attached: Different components will bring completely different styles of non-woven fabrics. The spunbonded fabric usually refers to polyester spunbond and polypropylene spunbond; and the styles of these two fabrics are very similar, which can be distinguished only by high temperature testing.

According to different production processes, non-woven fabrics can be classified as:

1. Spunlace Non-woven Fabric: It is to spray high-pressure fine water onto one or more layers of fiber webs to entangle the fibers with each other, so that the fiber webs can be reinforced and have a certain strength.

2. Heat-bonding Non-woven Fabric: It refers to adding fibrous or powdery hot-melt adhesive reinforcement material to the fiber web, and then the fiber web is heated, melted and cooled to reinforce into a cloth.

3. Pulp Air-laid Non-woven Fabric: It is also known as dust-free paper or dry paper non-woven fabric. It uses air-laid technology to open the wood pulp fiberboard into a single fiber state, and then uses air-flow method to agglomerate the fibers on the web curtain, and then reinforce the fiber web into a cloth.

4. Wet-laid Non-woven Fabric: It is to open the fiber raw material placed in the water medium into single fibers, and at the same time mix different fiber raw materials to form a fiber suspension slurry, which is then transported to the web forming mechanism, and the fibers form a net and then is reinforced into a cloth under wet state.

5. Spunbond Non-woven Fabric: It is after the polymer has been extruded and stretched to form continuous filaments, the filaments are laid into a web, and the web is then bonded by itself, thermally bonded, chemically bonded or mechanically reinforced to form non-woven cloth.

Attached: The relationship between non-woven fabric and spunbond fabric

Spunbond fabric and non-woven fabric are subordinate. There are many production processes for the manufacture of non-woven fabrics, and spunbond method is one of the non-woven fabric production processes.

6. Meltblown Non-woven Fabric: The process: polymer feeding --- melt extrusion --- fiber formation --- fiber cooling --- netting --- reinforcement into cloth.

7. Needle-punched Non-woven Fabric: It is a kind of dry-laid non-woven fabric. The needle-punched non-woven fabric uses the puncture effect of needle to reinforce the fluffy web into a cloth.

8. Stitched Non-woven Fabric: It is a kind of dry-laid non-woven fabric. The stitching method uses the warp-knitted loop structure to reinforce fiber webs, yarn layers, non-woven materials (such as plastic sheets, plastic or thin metal foils, etc.) or their combination to make a non-woven fabric.

According to different usage, non-woven fabrics can be classified as:

1. Medical and Sanitary Non-woven Fabrics: surgical gowns, coveralls, disinfection wraps, masks, diapers, civilian wipes, wipes, wet face towels, magic towels, soft towel rolls, beauty products, sanitary napkins, sanitary pads and disposable sanitary cloth, etc.;

2. Non-woven Fabrics for Home Decoration: wall coverings, tablecloths, bed sheets, bedspreads, etc.;

3. Non-woven Fabrics for Clothing: linings, fusible linings, wadding, shaped cotton, various synthetic leather base fabrics, etc.;

4. Industrial Non-woven Fabrics: filter materials, insulating materials, cement packaging bags, geotextiles, covering cloth, etc.;

5. Agricultural Non-woven Fabrics: crop protection cloth, seedling raising cloth, irrigation cloth, thermal insulation curtain, etc.;

6. Other Non-woven Fabrics: space cotton, thermal and sound insulation materials, linoleums, cigarette filters, tea bags, etc..

Plastic Film (LDPE/HDPE/CPE)

Impervious to fluids, polyethylene apparel provides maximum protection effectively. Unlike polypropylene, it resembles plastic more than cloth and lacks breathability. It is commonly used for brief episodes that require complete fluid protection.

LDPE --- is the low density version of PE. It has excellent resistance to water, moisture and most organic solvents and chemicals (except ones with aromatic or chlorine content). This has lower hardness, stiffness and strength compared to HDPE, but better ductility.

HDPE -- is the high density version of PE. It is highly resistant to many acids, alcalis and solvents. High density polyethylene is harder, stronger and a little heavier than LDPE, but is less ductile.

CPE --- Chlorinated polyethylene. It is a type of polymer, which is prepared from the substitution reaction of polyethylene and chlorine under the action of initiation. The products possess good waterproof, oil-proof, aging-resistant, chemical-resistant, ozone-resistant and fire-resistant properties.

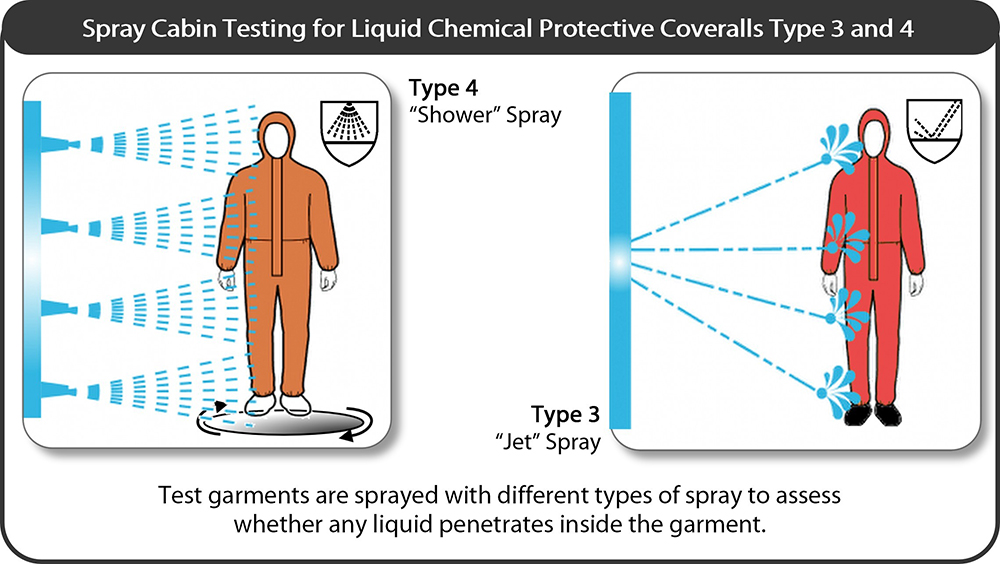

Garments Suitable for Type 3 and 4 Liquid Chemical Spray Protection

Type 3 & 4 garments are for protection against liquid sprays of hazardous chemicals.

The Types are defined by the "finished garment Type Tests"; tests on the whole garment which replicate the different types of liquid spray that might be found in real world applications. Both involve a test subject entering a cabin and being sprayed with a specific liquid in a specific format, emerging afterwards and with a defined method of identifying penetration of the liquid inside the garment with a pass or fail assessment. Whilst the liquid used is the same (lowered surface tension and died so any penetration is apparent) the difference in the type of spray is what defines each Type.

Type 3: a single jet spray applying considerable pressure and directed at possible weak points in the garment (such as seams and openings).

Type 4: a "shower-like" spray from four nozzles at the side of the cabin. Little pressure is applied from the spray on the garment but the garment is soaked over a one minute duration.

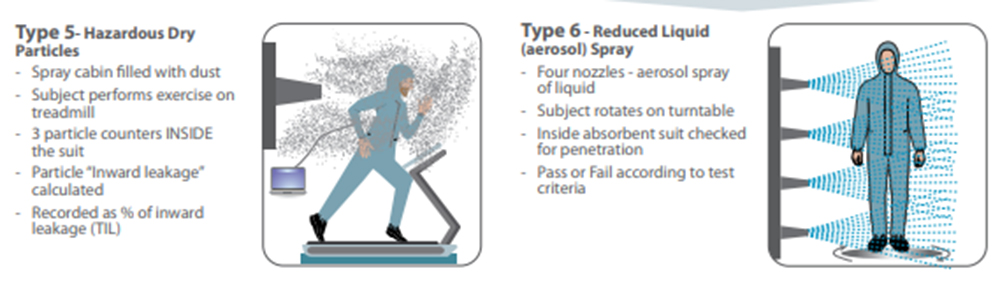

What is Type 5 & 6 Protection? Defined by CE Standards

Navigation

products

contact us